DRIVEN

BY PASSION

Since 1970

The interest in the serial industrial product allows him to express himself in different fields: electric bicycles for Prima Powerbike, woodworking machines of the SCM Group (Cms, Morbidelli, Gabbiani, Idm, Stefani, Routech, Minimax, Maros, Robopac), products AL-KO gardening tools, Marina System, Riello burners, Warcom sheet metal treatment machines, LEVEL technical snowboard gloves, Gimoka coffee machines.

Design Process

The design process is articulated starting from the conceptual sketch to the clay model that allows you to shape the volume on a 1: 1 scale, checking form and feasibility. With the aid of sophisticated software, the object is scanned and then the mathematics for serial production are developed.

CONCEPT

After various conceptual sketches, the one most relevant to the characteristics of the project is chosen.

REAL IMAGE

We move on to a photorealistic scale image, faithfully following the ergonomic and mechanical dimensions: engine, frame, suspension, tank, space for the helmet, etc. which is preparatory to the next phase.

CLAY MODEL

The clay model is a real sculpture, starting from the scale drawing, it shapes the vehicle bodywork, this system allows you to check the dimensions and reshape surfaces and details in full size to make the object as close as possible to the conception of the designer. Feasibility assessments are also made on the clay model: how to break down the body parts, check the actual dimensions and test the ergonomics. The model can be painted and finished in all details for presentations and assessments with competitors.

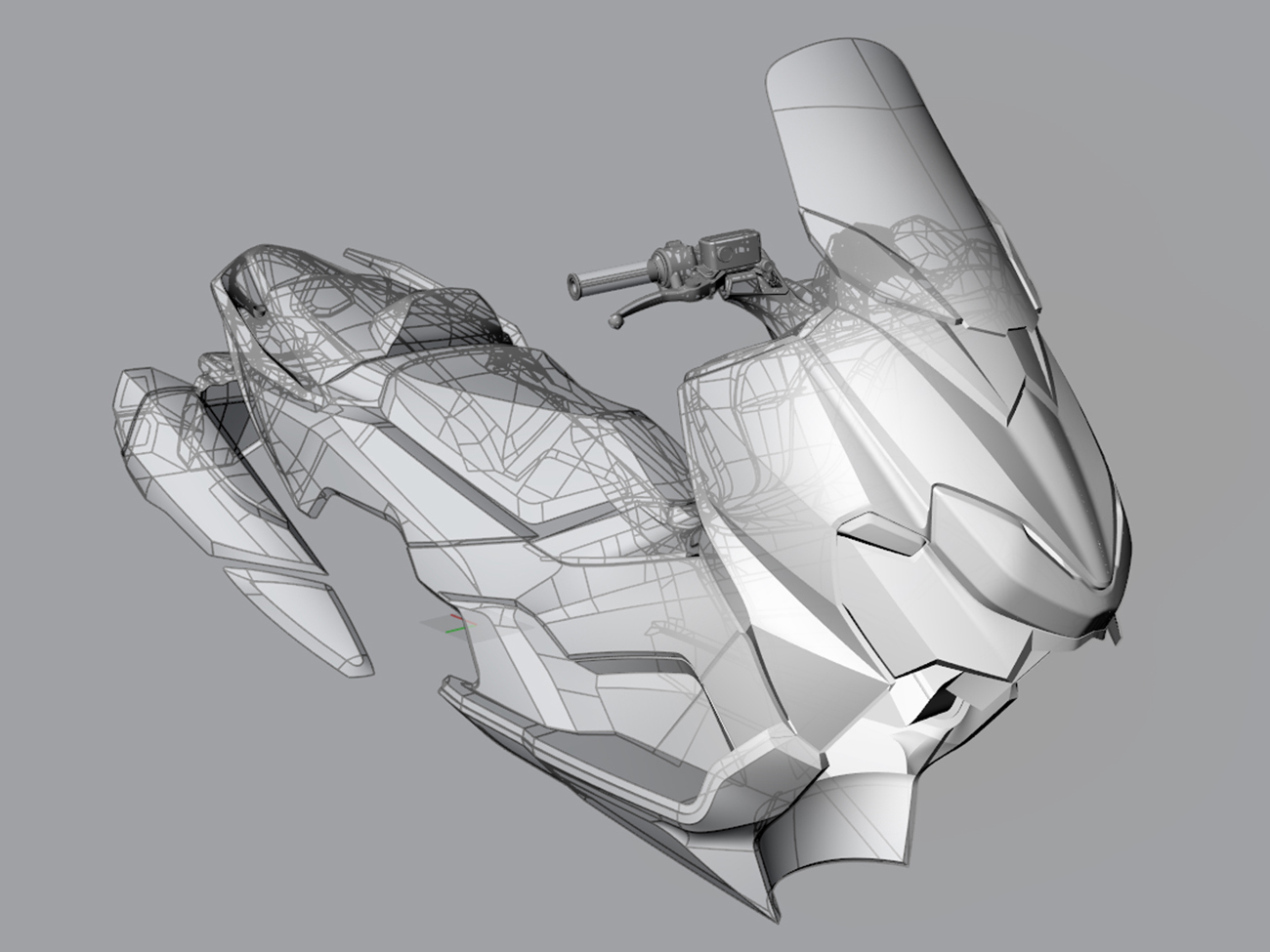

3D MODEL

The clay model is detected with the aid of a precision scanner obtaining a 3D file of the surfaces which are reworked with suitable software to obtain the drawings for production. This last engineering process is long and requires the contribution of competent and highly experienced staff.

FINAL PRODUCT

After hundreds of hours for drawings, bench tests, road tests, various prototypes and a huge investment, the product is on sale, to start production it took three years of work that involved dozens of people, from two distant parts of the world gave birth to an idea, turning it into reality.

Work Areas

Boat Design

I have always thought of lines that could meet both air and water.

Transportation Design

It all started with this great passion, that has always accompanied me.

Product Design

I believe that the design object was born when gesture meets elegance.